tri- ethylene glycol

Azin Commercial Industrial Group with more than 5 years of experience and activity in the field of production and supply of more than 20 types of chemical products, Provides you with Tri Ethylene Glycol (TEG), purity 99.8%.

Here you can see some TEG chemical information.

facts

These are just some of the facts that define us:

- Right management

- best technicians

- quality and workmanship

- lowest price

- customer care

- international standards

Introduction of ethylene oxide

Ethylene oxide, called Oxirane by IUPAC, is an organic compound with the formula C2H4O.

It is a cyclic ether and the simplest epoxide: a three-membered ring consisting of an oxygen atom and two carbon atoms.

Ethylene oxide is a slightly viscous liquid with a clear, colorless appearance and a sweet taste that emits virtually no odor. It’s often miscible with water, alcohol, and many similar organic compounds.

Ethylene oxide may polymerize exothermically if heated or contaminated.

If the polymerization takes place inside a container, the container may rupture violently

Process Description of Ethylene Glycol Plant

The schematic flow diagram of a commercial Ethylene oxide hydration plant shown below is designed to produce a maximum quantity of ethylene glycol. The raw materials for the plant are refined ethylene oxide and pure water. After being preheated by the exit product stream, these materials are mixed with recycled water and pumped into the hydration reactor. In the glycol reactor, sufficient time is provided for all the ethylene oxide to react.

The operating pressure of the reaction is controlled in a way to avoid or limit the vaporization of ethylene oxide from the aqueous solution.

Literature shows that commercial reactors operate at 190-200 ° C and will be at pressures 14-22 atm depending on the initial concentration of the oxide.

The water-glycol mixture from the reactor is fed to the first stage of a multi-stage evaporator, which is boiled with steam. The remaining stages operate at successively lower pressures, with the final stage normally being under vacuum. The evaporated water is recovered as condensate and recycled back to the glycol reaction feed mixing tank.

The water-free glycol solution is sent through a series of vacuum distillation towers to produce purified mono ethylene glycol and by-product di- and tri ethylene glycol.

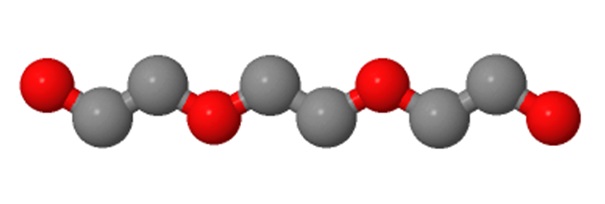

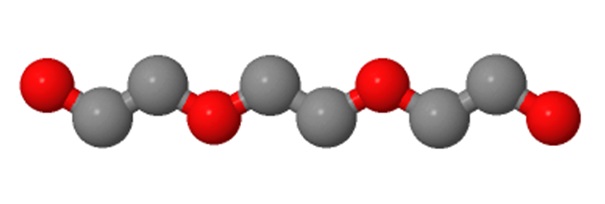

TEG chemical information

Tri-Ethylene Glycol (C6H14O4) is a colorless, viscous liquid with a slight odor.

it is non-flammable, mildly toxic and considered non-hazardous.

TEG is a member of a homologous series of dihydroxy alcohols.

It is used as a plasticizer for vinyl polymers as well as in the manufacture of air sanitizer and other consumer products.

TEG is commercially produced as a co-product of the oxidation of ethylene at a high temperature in the presence of a silver oxide catalyst.

Application usage of Tri-Ethylene Glycol

These applications are vital to the manufacturing of a wide variety of products, including: Antifreeze Coolants Chemical intermediates Gas dehydration and treating Heat transfer fluids Polyester resins Solvents Cement grinding aid

Chemical and physical properties of TEG

Analysis of TEG

Model development

Natural gas usually contains a large amount of water and is fully saturated during production operations.

In natural gas dehydration units’ water vapor is removed from natural gas streams to meet sales specifications or other downstream gas processing requirements. Many methods and principles have been developed in the natural gas dehydration process for gaining a high level of tri-ethylene glycol (TEG) purity. Among them, reducing the pressure in the reboiler at constant temperature results in higher glycol purity

TEG safety information and maintenance

According to the safety and chemical information sheet of triethylene glycol solvent, it is necessary to pay attention to the following:

- Acording to the TEG chemical information, Triethylene glycol has high toxicity.

- Eating ethylene glycol affects the central nerves and causes confusion.

- Contact with the eyes causes irritation, inflammation and swelling of the eyelids.

- If triethylene glycol comes in contact with the skin, it may itch and irritate the skin.

- This compound produces toxic fumes when burned. Therefore, if you inhale this substance, take the injured person to the open air immediately, and it is necessary to see a doctor to receive medical care.

Schema of gas stripping section in NG dehydration unit

Azin Commercial Industrial Group with more than 5 years of experience and activity in the field of production and supply of more than 20 types of chemical products, Provides you with Tri Ethylene Glycol (TEG), purity 99.8%.

For more information about the products and place order please contact us.

We try to provide you best Product withe easy and fast delivery around the world withoute delay.

It’ll be our pleasure to know your opinion and experience or any point of view in which Azin can performs better.

Comment your outlook on TEG commerce